- Liquid based AM

- Solid based AM

- Powder based AM

Liquid based AM

|

| SLA Process (Image Source: laserfocusworld.com). |

|

| Solid Ground Curing Process (image Source: hisour.com). |

Solid based AM

| |

| Fused Filament Fabrication process (Dolores R Serrano et al.) | . |

|

| Laminated Object Manufacturing (LOM) (Image source: custompartnet). |

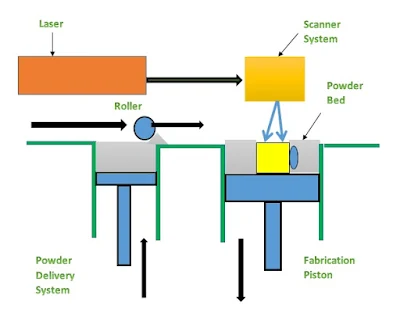

Powder based AM

|

| Selective Laser Sintering Process (Image Source: manufactur3dmag.com). |

Although, as per ASTM standard F2797, 3D printing methods are categorized into seven groups:

- Extrusion based Processes

- Material Jetting Processes

- Powder Fusion based Processes

- Vat Polymerization Processes

- Sheet Lamination Processes

- Direct Energy Deposition Processes

- Binder Jetting Processes

S.No. |

Category |

3D Printing Processes |

| 1 |

Extrusion based Processes |

Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF) |

| 2 |

Material Jetting Processes |

Material Jetting |

| 3 |

Powder Fusion based Processes |

Direct Metal Laser Sintering (DMLS), Electron Beam Melting (EBM),

Selective Heat Sintering (SHS), Selective Laser Melting (SLM) and

Selective Laser Sintering (SLS). |

| 4 |

Vat Polymerization Processes |

Stereolithography (SLA) |

| 5 |

Sheet Lamination Processes |

Ultrasonic Additive Manufacturing (UAM) and Laminated Object Manufacturing (LOM) |

| 6 |

Direct Energy Deposition Processes |

Laser Engineered Net Shaping (LENS), Directed Light Fabrication, Direct Metal Deposition, 3D Laser Cladding |

| 7 |

Binder Jetting Processes |

3DP Technology |

References

- Krishnanand, Taufik M. (2021) Fused Filament Fabrication (FFF) Based 3D Printer and Its Design: A Review. In: Deepak B.B.V.L., Parhi D.R.K., Biswal B.B. (eds) Advanced Manufacturing Systems and Innovative Product Design. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-9853-1_41

Comments

Post a Comment