Introduction: Additive Manufacturing

Additive manufacturing uses data computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. As its name implies, additive manufacturing adds material to create an object. By contrast, when you create an object by traditional means, it is often necessary to remove material through milling, machining, carving, shaping or other means.

Although the terms "3D printing" and "rapid prototyping" are casually used to discuss additive manufacturing, each process is actually a subset of additive manufacturing.

Additive Manufacturing Processes

Binder Jetting

This technique uses a 3d printing style head moving on x, y and z axes to deposit alternating layers of powdered material and a liquid binder as an adhesive.

Directed Energy Deposition

Direct energy deposition additive manufacturing can be used with a wide variety of materials including ceramics, metals and polymers. A laser, electric arc or an electron beam gun mounted on an arm moves horizontally melting wire, filament feedstock or powder to build up material as a bed moves vertically.

Material Extrusion

This common AM process uses spooled polymers which are either extruded or drawn through a heated nozzle which is mounted on a movable arm. These builds melted material layer by layer as the nozzle moves horizontally and the bed moves vertically. The layers adhere through temperature control or chemical bonding agents.

Powder Bed Fusion

Powder bed fusion encompasses a variety of AM techniques including direct metal laser melting (DMLM), direct metal laser sintering (DMLS), electron beam melting (EBM), selective laser sintering (SLS) and selective heat sintering (SHS). Electron beams, lasers or thermal print heads are used to melt or partially melt fine layers of material after which excess powder is blasted away.

Sheet Lamination

Sheet lamination can be split into two technologies; laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). Laminated object manufacturing is suited to creating items with visual or aesthetic appeal and uses alternate layers of paper and adhesive. UAM uses ultrasonic welding to join thin metal sheets; a low energy, low temperature process, UAM can be used with various metals such as aluminum, stainless steel and titanium.

Vat Polymerization

This process uses a vat of liquid resin photo-polymer to create an object layer by layer. Mirrors are used to direct ultraviolet light which cures the successive layers of resin through photo-polymerization.

Wire Arc Additive Manufacturing (Now known as Directed Energy Deposition-Arc (DED-arc))

Wire arc additive manufacturing uses arc welding power sources and manipulators to build 3D shapes through arc deposition. This process commonly uses wire as a material source and follows a predetermined path to create the desired shape. This method of additive manufacture is usually performed using robotic welding equipment.

Fused Filament Fabrication (FFF)

FFF 3D printing, or fused filament fabrication, is an additive manufacturing (AM) process in which thermoplastic material is pushed through a heated nozzle to create objects layer by layer. A typical FFF 3D printer, therefore, takes a polymer-based filament and forces it through a heated nozzle, which melts the material and deposits it in 2D layers on the build platform. While still warm, these layers fuse with each other to eventually create a three-dimensional part. Generally accepted as the simplest way to 3D print stuff, FFF is accessible, reasonably efficient, and widely popular.

|

| Fused Filament Fabrication Process Schematic |

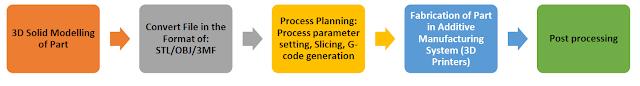

Working Procedure of Additive Manufacturing

Create a Design

The first step of 3D printing typically starts on a computer. You must create your design using a 3D design software, typically a CAD (computer-aided design) software.

Export the STL/OBJ/3MF File

Once you have created or chosen a design, you must either export or save as the STL file. The STL file is what stores the information about your conceptual 3D object. Many other file formats such as OBJ, 3MF, etc. can also be used.

Select the Materials

There are many different 3D printing materials available, and you can choose them based on the properties that you want your object to have. In this experiment we will be using Polylactic Acid (PLA).

Process Planning

Import the STL file in some process planning software like Cura. Select the position and orientation of the part on the build plate. Then select all the process parameters as per the requirement. After selecting the process parameters, slice the part to generate the G-Code.

Part Fabrication

Transport the G-Code to the additive manufacturing system (3D printer) and command the machine to start the printing of the part.

Post Processing

Parts manufactured with 3D printing technologies usually require some degree of post-production treatment. This important step of the 3D printing process is known as post-processing. In short, post-processing in 3D printing refers to any process or task that needs to be performed on a printed part, or any technique used to further enhance the object. The options for post-processing 3D printed parts include removing support or excess material, washing and curing, sanding or polishing a model to painting or coloring.

Conclusion

We learned the basic concept of additive manufacturing, through the demonstration Fused Filament Fabrication process. We learned about the various parts of FFF 3D printer and its working and get detailed hands-on practice by printing the part using PLA material.

Comments

Post a Comment