Created as a showcase project, AMAZE-28, the single-room summer house, was successfully constructed within 28 days on the grounds of the Kerala State Nirmithi Kendra. The 3D-printed building at the Kerala State Nirmithi Kendra in Thiruvananthapuram. (Photo: Shekunj) The inauguration of Kerala's inaugural 3D-printed structure, a 380-square-foot single-room summer house, is scheduled to take place on October 10 at the Kerala State Nirmithi Kendra (Kesnik) campus located in PTP Nagar, Thiruvananthapuram. Conceived as a showcase initiative, the summer house named AMAZE-28 was successfully finished within a mere 28 days. This impressive project was executed by Tvasta, a construction technology startup based in Chennai, founded by alumni of IIT-Madras, who have entered into a memorandum of understanding (MoU) with Kesnik. AMAZE-28 is perched upon a concrete foundation atop a gentle elevation within the Kesnik campus. Febi Varghese, the Director and Chief Executive Officer of...

I have YouTube channel as well, for my channel I decided to make showpiece containing the name of channel. I wanted to place that showpiece on my table while recording the video for my channel. Hence, I came up with an idea to use 3D printing, laser engraving and some electronics items to make this showpiece. In this article, I am explaining the complete fabrication process for making that showpiece.

Part and Components used

In this project, following components has been used:

- PLA Filament (For 3D Printing)

- Acrylic sheet with engraved channel name

- LED Strip

- 5mm DC Jack

- 12V DC Power source

- Glue to assemble the 3D printed parts

- Soldering iron

- Computer to design the housing/casing

Laser Engraving

I choose a 150mmX30mmX5mm acrylic sheet strip to engrave the name of my website/ Youtube channel (TechKnowLab) with the help of laser engraving machine. The engraved part is shown below.

Designing

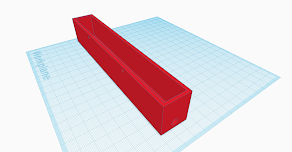

Next step is to design the housing/casing that can house this engraved part and LED strip. I want to 3D print this part, hence I need CAD model of all the parts. I have designed all the parts on Tinkercad. All the part images and CAD files are listed below.

3D Printing the Parts

All the designed parts (above) were fabricated using fused filament fabrication based 3D printing process. The material used for the 3D printing is PLA. All the 3D printed parts are given below.

|

| Final working prototype of the logo showpiece. |

Now the project is assembled and working properly. Comment below how it is looking?

Comments

Post a Comment